Most products we consume, technologies we use and services we rely on are produced and issued at scale and speed never seen before at lower costs and without compromising quality.

Examples include large scale food production, augmentation of chemicals, production of human injectable solutions in sterile environments, and the mixing and filling of gas cylinders, bottles, and receptacles.

Process Control is not just automation. It is the optimisation of production systems and processes through precise measurement and control of variables including flow, level, pressure, temperature, and vibration.

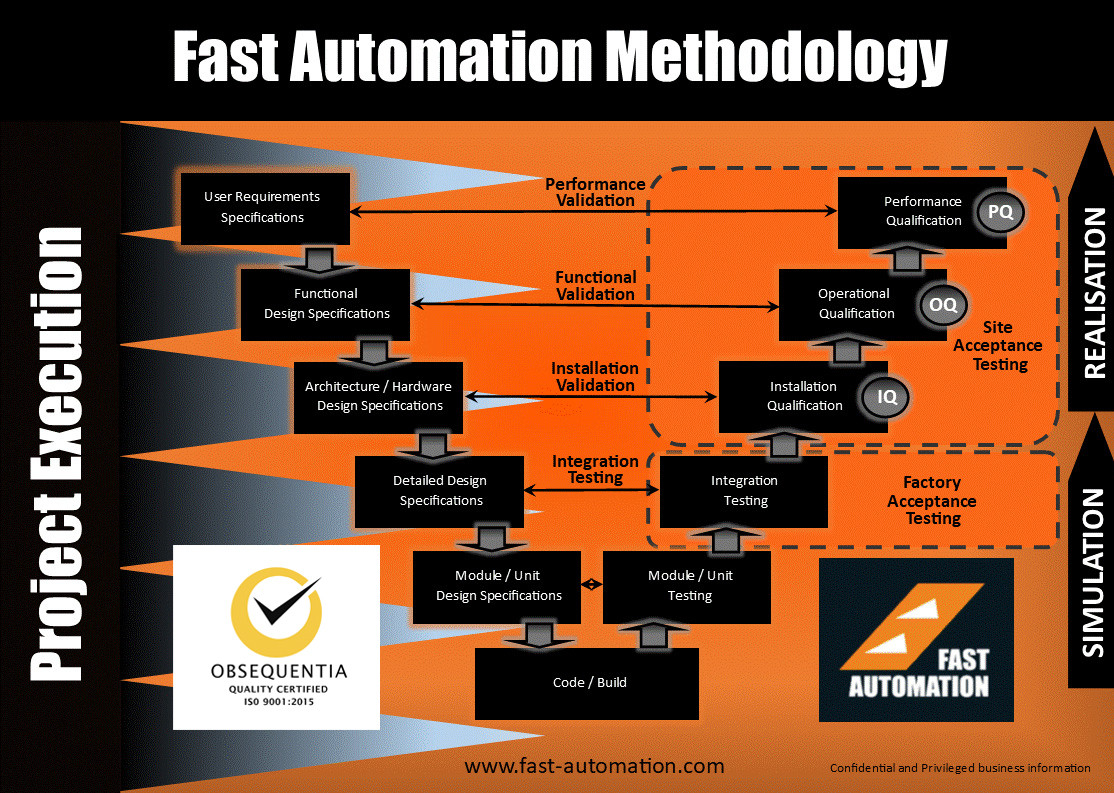

Fast Automation has implemented hundreds of Process Control solutions for small and large well known businesses for over 24 years. We follow GAMP5 (Good Automated Manufacturing Practice) guidelines and utilises a lifecycle V-model and traceability matrix to ensure complete compliance to our customer’s requirements. Providing fully documented system design, development and validation to ensure compliance with FDA, TGA, Medsafe and other regulators.

Human Injectable Solution Preparation Process Control Systems

Fast Automation is presently finishing the delivery of several solution preparation systems for a major pharmaceutical company.

The suites are used to automate the manufacture of solutions for human injection and comprise the following:

Respule Solution Project

Fast Automation was awarded a contract to provide an Electrical Control System and Software on a complex system for the automated preparation of respule solutions. The contract was worth approximately $1M and utilised Siemens S7-400 PLC and Wonderware technology together with Festo CPX remote I/O valve blocks.

For more information on how Fast Automation can assist you to ensure your processes are performing at their most effective level, please contact us for an appointment.